AWI 300 - Materials

3.2 Lumber

3.2.1 Lumber Grading

a) Lumber Association rules shall not be used, since even their highest s permit defects unacceptable in Product and are not based upon the use of the whole but, rather on a percentage of the board. Lumber rules in this standard apply only to wood surfaces visible after manufacture and installation.

b) grade rules in this standard apply to boards exceeding 6.4 mm [.250”] in thickness.

3.2.2 Moisture Content of Lumber

3.2.3 Lumber for Exterior Use

3.2.4 Methods of Sawing

3.2.5 Filling of Natural Characteristics

3.2.6 Unlisted Species Rules

3.2.7 Adhesive Requirements

a) When gluing lumber for thickness and/or width or lay-up of veneered construction, the appropriate adhesive shall be used in accordance with manufacturer/supplier’s documented instructions and be:

| Adhesive Type | Use Case |

|---|---|

| Type I | For Non-Climate Controlled Interior or Exterior |

| Type II | For Use |

3.2.8 Dimensional Requirements

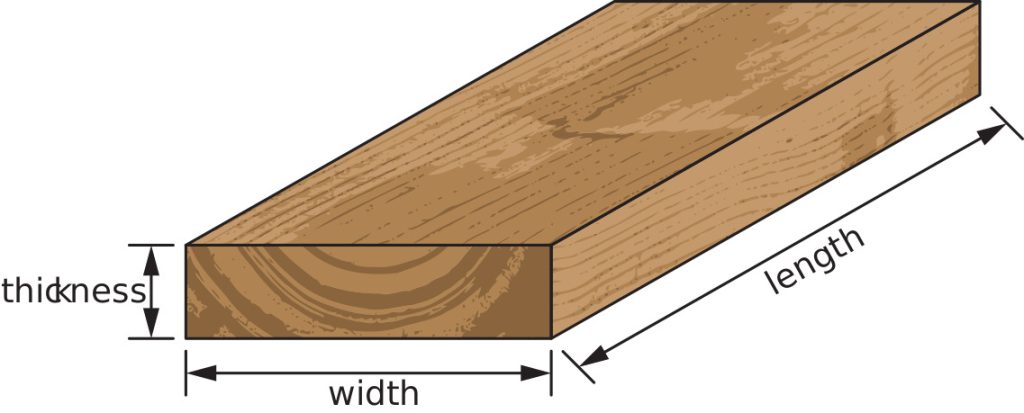

a) Lumber dimensions are specified in the following order: by thickness, followed by width (across the grain), followed by length (along the grain). (See Figure 65)

Figure 65

a) Lumber and profiled components shall be:

| Nominal Measurement | Rough Thickness | = | Milled Thickness |

|---|---|---|---|

| 4/4 | 25.4 mm [1″] | = | 19.1 mm [.750″] |

| 5/4 | 31.8 mm [1.250″] | = | 25.4 mm [1″] |

| 6/4 | 38.1 mm [1.500″] | = | 31.8 mm [1.250″] |

| 8/4 | 50.8 mm [2″] | = | 44.4 mm [1.687″] |

| 10/4 | 63.5 mm [2.500″] | = | 55.6 mm [2.189″] |

| 12/4 | 76.2 mm [3″] | = | 68.2 mm [2.687″] |

| 16/4 | 101.6 mm [4″] | = | 93.6 mm [3.687″] |

b) When , a reduction of .8 mm [.031″] off the thicknesses shown in this table is permitted.

3.2.9 Special Characteristics

3.2.10 Hardwood Requirements

a) material requirements apply only to the following commonly-used species:

| Scientific Name | |

|---|---|

| Alder | Alnus spp. |

| Anigre | Pouteria spp. |

| Ash | Fraxinus spp. |

| Basswood | Tilia americana |

| Beech | Fagus spp. |

| Birch | Betula spp. |

| Cherry, black | Prunus spp. |

| Hickory | Carya spp. (excluding C. illinoinensis, C. aquatica, C. cordiformis, and C. myristiciformis) |

| Lauan (Meranti) | Shorea spp. |

| Mahogany, African | Khaya spp. |

| Mahogany, American | Swietenia spp. |

| Mahogany, Asian/Australian | Toona spp. (including T. calantas) |

| Makore | Tieghemella spp. |

| Maple, hard | Acer saccharum or A. nigrum |

| Maple, soft | Acer spp. (excluding saccharum and nigrum) |

| Oak, red | Quercus spp. (including rubra) |

| Oak, white | Quercus spp. (including alba) |

| Pecan | Carya illinoinensis, C. aquatica, C. cordiformis, and C. myristiciformis |

| Poplar | Liriodendron tulipifera |

| Sapele | Entandrophragma cylindricum |

| Teak | Tectona grandis |

| Walnut, black | Juglans spp. |

a) Is permitted at the option of the manufacturer/supplier for hardwoods, when finished dimensions exceed 27 mm [1.063”]. (See Figure 67)

a) Allowances for the quantity, proximity, size, and distribution of natural characteristics in any one board’s exposed face for :

| Characteristic | Premium | Custom | Economy |

|---|---|---|---|

| Characteristics permitted | None in any face smaller than 258,064 mm sq. [400″ sq.] | None in any face smaller than 193,548 mm sq. [300″ sq.] | None in any face smaller than 192,032 mm sq. [200″ sq.] |

| One permitted for each additional 129,032 mm sq. [200″ sq.] | One permitted for each additional 96,774 mm sq. [150″ sq.] | One permitted for each additional 65,516 mm sq. [100″ sq.] | |

| Max 3 per board | Max 4 per board | Max 5 per board | |

| No knots, pitch pockets/ within 914 mm [36″] of one another | No knots, pitch pockets/streaks within 610 mm [24″] of one another | No knots, pitch pockets/streaks within 457 mm [18″] of one another | |

| None | None | None | |

| Bird’s eye, sound or filled | Unlimited | Unlimited | Unlimited |

| , sound | <19.1 mm [.750″] dia. | <25.4 mm [1″] dia. | <25.4 mm [1″] dia. |

| Check, filled | <1 mm W x 101.6 mm L [.039″ x 4″] | <2 mm W x 152.4 mm L [.078″ x 6″] | <2 mm W x 299 mmL [.078″ x 9″] |

| None | None | None | |

| , sound & tight | <9.5 mm [.375″] dia. | <15.9 mm [.625″] dia. | <25.4 mm [1″] dia. |

| Knot, checked & filled | <6.4 mm [.250″] dia. | <12.7 mm [.500″] dia. | <19.1 mm [.750”] dia. |

| , filled | <3.2 mm [.125″] dia. | <6.4 mm [.250″] dia. | <12.7 mm [.500″] dia. |

| Mineral stain/ streak | Unlimited | Unlimited | Unlimited |

| ≤ 38.1 mm [1.500″] W x 88.9 mm L [3.500″] | ≤ 38.1 mm [1.500″] W x 88.9 mm L [3.500″] | ≤ 38.1 mm [1.500″] W x 88.9 mm L [3.500″] | |

| /, filled | <2 mm [.078″] W x 76.2 mm [3″] L or 3.2 mm [.125″] x 50.8 mm [2″] | <2 mm [.078″] W x 152.4 mm [6″] L or 3.2 mm [.125″] W x 101.6 mm [4″] L | <2 mm [.078″] W x 152.4 mm [6″] L or 3.2 mm [.125″] W x 101.6 mm [4″] L |

| Sapwood | Unlimited | Unlimited | Unlimited |

| , filled | ≤1.6 mm [.063″] W x 50.8 mm [2″] | ≤3.2 mm [.125″] W x 76.2 mm [3″] L | ≤6.4 mm [.250″] W x 76.2 mm [3″] L |

| Split, filled | ≤.8 mm [.031″] W x 101.6 mm [4″] L | ≤1.6 mm [.063″] W x 152.4 mm [6″] L | ≤2.4 mm [.094″] W x 203 mm [8″] L |

| Sticker shadow | Unlimited | Unlimited | Unlimited |

| Wormholes, filled | None | ≤1.6 mm [.063″] in diameter | 3.2 mm [.125″] in diameter |

a) Matching, when glued for thickness/width or when veneered construction, shall be:

| Premium | Custom | Economy |

|---|---|---|

| Not required |

a) Allowances for the quantity, proximity, size, and distribution of natural characteristics in any one board’s exposed face for transparent finish for all hardwoods:

| Characteristic | Premium | Custom | Economy |

|---|---|---|---|

| Characteristics permitted | 2 ea. without knots, pitch pockets/streaks within 1219 mm [48″] of one another. | 3 ea. without knots, pitch pockets/streaks within 914 mm [36″] of one another. | 4 ea. without knots, pitch pockets/streaks within 610 mm [24″] of one another. |

| Bark pocket | None | None | None |

| Bird’s eye, sound | Unlimited | Unlimited | Unlimited |

| Bird’s eye, checked | None | ≤ 10% of face | Unlimited |

| Burl, sound | ≤ 12.7 mm [.500″] dia. | ≤ 25.4 mm [1″] dia. | Unlimited |

| Check | ≤ .8 mm [.031″] W x 101.6 mm [4″] L | ≤ 1.6 mm [.063″] W x 152.4 mm [6″] L | ≤ 2.4 mm [.094″] W x 203 mm [8″] L |

| Heartwood in select white ash, birch, and maple | None | None | None |

| Honeycomb | None | None | None |

| Knot, sound and tight | ≤ 3.2 mm [.125″] dia. | ≤ 6.4 mm [.250″] dia. | ≤ 9.5 mm [.375″] dia. |

| Knot, checked | None | ≤ 6.4 mm [.250″] dia. | ≤ 12.7 mm [.500″] dia. |

| Knot hole | None | None | None |

| Mineral Stain | None | 10% of face | Unlimited |

| Patch | None | ≤ 38.1 mm [1.500″] w x 88.9 mm [3.500″] L | ≤ 38.1 mm [1.500″] w x 88.9 mm [3.500″] L |

| Inconspicuous from 914 mm [36″] | Inconspicuous from 1524 mm [60″] | ||

| Pitch pocket/ streak | None | None | ≤ 1.6 mm [.063″] W x 152.4 mm [6″] L or 3.2 mm [.125″] W x 101.6 mm [4″] L |

| Sapwood in unselected species | Unlimited | Unlimited | Unlimited |

| Sapwood in red birch and brown ash | None | None | None |

| Sapwood in black cherry and black walnut | ≤ 5% of face | ≤ 10% of face | Unlimited |

| Shake | None | None | ≤ 3.2 mm [.126″] W x 76.2 mm [3″] L |

| Split | ≤ .8 mm [.031″] W x 101.6 mm [4″] L | ≤ 1.6 mm [.063″] W x 152.4 mm [6″] L | ≤ 2.4 mm [.094″] W x 203 mm [8″] L |

| Sticker shadow | None | None | ≤ 10% of face |

| Wormhole, filled | None | ≤ 1.6 mm [.063”] dia. | ≤ 3.2 mm [.125”] dia. |

a) Lumber referred to as American mahogany shall be of the Swietenia genus. Lumber referred to as African mahogany shall be of the Khaya genus. Lumber referred to as Philippine mahogany shall be of the Shorea or Toona genus and may also be referred to as lauan, tanguile, meranti, or kalantas.

a) Tolerances for the quantity, proximity, and distribution of natural characteristics in any one board’s exposed face for transparent finish for:

b) Alder, natural ash, natural birch, lauan, American mahogany, African mahogany, natural hard maple, natural soft maple, poplar, red oak, white oak, and teak:

| Premium | Custom | Economy |

|---|---|---|

| None in any face smaller than 387,096 mm sq. [600″ sq.] | None in any face smaller than 258,064 mm sq. [400″ sq.] | None in any face smaller than 193,548 mm sq. [300″ sq.] |

| One permitted for each additional 129,032 mm sq. [200″ sq.] | One permitted for each additional 96,744 mm sq. [150″ sq.] | One permitted for each additional 64,516 mm sq. [100″ sq.] |

c) For select brown ash, select red and white birch, and select white maple

| Premium | Custom | Economy |

|---|---|---|

| None in any face smaller than 322,580 mm sq. [500″ sq.] | None in any face smaller than 225,806 mm sq. [350″ sq.] | None in any face smaller than 129,032 mm sq. [200″ sq.] |

| One permitted for each additional 12,039 mm sq. [200″ sq.] | One permitted for each additional 96,774 mm sq. [150″ sq.] | One permitted for each additional 64,516 mm sq. [100″ sq.] |

d) For black cherry, white oak, red oak, and black walnut:

| Premium | Custom | Economy |

|---|---|---|

| None in any face smaller than 193,548 mm sq. [300″ sq.] | None in any face smaller than 129,032 mm sq. [200″ sq.] | None in any face smaller than 96,744 mm sq. [150″ sq.] |

| One permitted for each additional 96,774 mm sq. [150″ sq.]. | One permitted for each additional 64,516 mm sq. [100″ sq.] | One permitted for each additional 48,387 mm sq. [75″ sq.] |

3.2.11 Softwood Materials

a) materials apply to western red cedar, ponderosa pine, sugar pine, eastern white pine, eastern white cedar, hemlock, Douglas fir, and redwood. For species not listed, length requirements and size/exposed area of permitted natural characteristics shall be as agreed to between owner/design professional and manufacturer/supplier.

b) Apply only to the following commonly-used species:

| Common Market Name | Scientific Name |

|---|---|

| Douglas-Fir | Pseudotsuga menziesii |

| Redwood | Sequoia sempervirens |

| Cedar, red | Thuja plicata, Juniperus virginiana, Toona ciliata |

| Cedar, white | Chamaecyparis thyoides, Cupressus lusitanica, Thuja occidentalis |

| Cedar, other | Cryptomeria japonica, Melia azedarach |

| Pine | Pinus spp. |

a) Is permitted at the option of the manufacturer/supplier for softwoods, when finished dimensions exceed 38.1 mm [1.500”]. (See Figure 67)

a) Is permitted when finished dimensions exceed 178 mm [7”]. (See Figure 66)

| Premium | Custom | Economy |

|---|---|---|

| Components shall be well matched for color and grain. | Components shall be compatible for color and grain. | No matching for color or grain required. |

a) Natural characteristics are permitted only if they are inconspicuous after final finish.

b) Tolerances for the quantity, proximity, and distribution of natural characteristics in any one board’s exposed face when inconspicuous after final finish:

| Characteristic | Premium | Custom | Economy |

|---|---|---|---|

| Characteristics permitted | None in any face smaller than 387,096 mm sq. [600″ sq.] | None in any face smaller than 258,064 mm sq. [400″ sq.] | None in any face smaller than 129,032 mm sq. [200″ sq.] |

| One permitted for each additional 129,032 mm sq. [200″ sq.] | One permitted for each additional 96,774 mm sq. [150″ sq.] | One permitted for each additional 64,516 mm sq. [100″ sq.] | |

| Max 3 per board | Max 4 per board | Max 5 per board | |

| No knots, pitch pockets/streaks within 914 mm [36”] of one another | No knots, pitch pockets/streaks within 610 mm [24”] of one another | No knots, pitch pockets/streaks within 457 mm [18”] of one another | |

| Bark pocket | None | None | None |

| Bird’s eye, sound or filled | Unlimited | Unlimited | Unlimited |

| Burl, sound | <19.1 mm [.750″] dia. | <25.4 mm [1″] dia. | <25.4 mm [1″] dia. |

| Check, filled | <.8 mm [.031″] W x 101.6 mm [4″] L | <1.6 mm [.063″] W x 152.4 mm [6″] L | <2.4 mm [.094″] w x 229 mm [9″] L |

| Honeycomb | None | None | None |

| Knot, sound & tight | < 9.5 mm [.375″] dia. | < 15.9 mm [.625″] dia. | < 25.4 mm [1″] dia. |

| Knot hole, filled | < 3.2 mm [.125″] dia. | < 6.4 mm [.250″] dia. | < 12.7 mm [.500″] dia. |

| Mineral Stain/ | Unlimited | Unlimited | Unlimited |

| Patch | ≤ 38.1 mm [1.500″] w x 88.9 mm [3.500″] L | ≤ 38.1 mm [1.500″] w x 88.9 mm [3.500″] L | ≤ 38.1 mm [1.500″] w x 88.9 mm [3.500″] L |

| Pitch Pocket/Pitch Streak | < 1.6 mm [.063″] W x 76.2 mm [3″] L or 3.2 mm [.125″] x 50.8 mm [2″] | < 1.6 mm [.063″] W x 152.4 mm [6″] L or 3.2 mm [.125″] x 101.6 mm [4″] | < 1.6 mm [.063″] W x 152.4 mm [6″] L or 3.2 mm [.125″] x 101.6 mm [4″] |

| Sapwood | Unlimited | Unlimited | Unlimited |

| Shake, filled | ≤ 1.6 mm [.063″] W x 50.8 mm [2″] L | ≤ 3.2 mm [.125″] W x 76.2 mm [3″] L | ≤ 6.4 mm [.250″] W x 76.2 mm [3″] L |

| Split, filled | ≤ .8 mm [.031″] W x 101.6 mm [4″] L | ≤ 1.6 mm [.063″] W x 152.4 mm [6″] L | ≤ 2.4 mm [.094″] W x 203 mm [8″] L |

| Sticker Shadow | Unlimited | Unlimited | Unlimited |

| Wormhole, filled | None | 1.6 mm [.063″] dia. | 3.2 mm [.125″] |

a) Tolerances for the quantity, proximity, and distribution of natural characteristics in any one board’s exposed face when inconspicuous after final finish:

| Characteristic | Premium | Custom | Economy |

|---|---|---|---|

| Characteristics permitted | None in any face smaller than 580,644 mm sq. [900″ sq.] | None in any face smaller than 387,096 mm sq. [600″ sq.] | None in any face smaller than 258,064 mm sq. [400″ sq.] |

| One permitted for each additional 258,064 mm sq. [400″ sq.] | One permitted for each additional 193,548 mm sq. [300″ sq.] | One permitted for each additional 129,032 mm sq. [200″ sq.] | |

| Max 2 per board | Max 3 per board | Max 4 per board | |

| No knots, pitch pockets/streaks within 1219 mm [48″] of one another | No knots, pitch pockets/streaks within 914 mm [36″] of one another | No knots, pitch pockets/streaks within 610 mm [24″] of one another | |

| Bark pocket | None | None | None |

| Bird’s eye, sound or filled | Unlimited | Unlimited | Unlimited |

| Bird’s eye, checked | None | ≤ 10% of face | Unlimited |

| Burl, sound | ≤ 12.7 mm [.500″] dia. | ≤ 15.9 mm [.625″] dia. | ≤ 19.1 mm [.750″] dia. |

| Check | < .8 mm [.031″] W x 101.6 mm [4″] L | < 1.6 mm [.063″] W x 152.4 mm [6″] L | < 2.4 mm [.094″] W x 203 mm [8″] L |

| Honeycomb | None | None | None |

| Knot, sound and tight | < 6.4 mm [.250″] dia. | < 12.7 mm [.500″] dia. | < 19.1 mm [.750″] dia. |

| Knot hole | None | None | None |

| Mineral stain/ mineral streak | None | ≤ 10% of face | Unlimited |

| Patch | None | ≤ 38.1 mm [1.500″] w x 88.9 mm [3.500″] L | ≤ 38.1 mm [1.500″] w x 88.9 mm [3.500″] L |

| Inconspicuous at 914 mm [36”] | Inconspicuous at 1524 mm [60”] | ||

| Pitch pocket/pitch streak | None | <1.6 mm [.063”] W x 76.2 mm [3”] L or 3.2 mm [.125”] x 50.8 mm [2”] | <1.6 mm [.063”] W x 152.4 mm [6”] L or 3.2 mm [.125”] x 101.6 mm [4”] |

| Sapwood in unselected species | Unlimited | Unlimited | Unlimited |

| Sapwood in all heart redwood | None | None | None |

| Shake | None | ≤ 1.6 mm [.063″] W x 50.8 mm [2″] L | ≤ 3.2 mm [.125″] W x 76.2 mm [3″] L |

| Split | None | ≤ .8 mm [.031″] W x 101.6 mm [4″] L | ≤ 1.6 mm [.063″] W x 152.4 mm [6″] |

| Sticker shadow | None | None | 10% of face |

| Wormhole, filled | None | ≤1.6 mm [.063″] dia. | ≤ 3.2 mm [.126″] dia. |