ANSI/AWI SMA 0643-2021 - Wood Stair, Handrail, and Guard Systems

3.4 Aesthetic

a) Tolerances for s shall be in accordance with AWI 300 – Materials Standard.

b) Where matching of “rustic” styles or finishes and/ or reclaimed materials is specified, number of permitted shall be as agreed to between owner/design professional and .

c) Residual marks, including adhesive and filler residue, on exposed and semiexposed surfaces shall be removed.

d) Fasteners shall be concealed

e) Fastener in pre-finished Product 4.8 mm [.188″] or smaller shall be filled by the with matching filler (putty) furnished by the manufacturer/supplier.

f) Plugs are permitted provided they are sanded flush and , , and grain direction.

g) Fastener holes in Product larger than 4.8 mm [.188″] shall be filled by the installer with plugs furnished by the manufacturer/supplier.

h) Unless otherwise indicated within this standard, Product shall be installed free of , visible machine marks, ing (excluding turned surfaces), tear-out, nicks, chips, scratches, layout lines, pencil lines, and/or defects exceeding the quantity and/or size limits defined in the AWI 300 – Materials Standard (latest edition).

i) Exposed surfaces of all materials shall be free of tooling and marks and sanded to a minimum of:

| Premium | Custom | Economy |

|---|---|---|

| 150-grit finish | 120-grit finish | 100-grit or 15 |

j) Wood selected to make up components shall be joined and glued. Joinery shall be inconspicuous.

k) Reveals shall be consistent between like parts throughout the system.

l) s used for the same purpose, within the scope of this standard, shall be consistent throughout a project.

m) is not permitted.

3.4.1 Transparent Finish

a) Shall be finished with a finishing technology (See AWI Finishing Standard, latest edition) of the ‘s choice.

b) Exposed faces:

| Premium | Custom | Economy |

|---|---|---|

| Shall be between like and components of the same material | Shall be compatible for color and grain between like and adjacent components of the same material | Shall be compatible for color between like and adjacent components of the same material |

3.4.2 Opaque Finish

a) Shall be finished with a finishing technology (See AWI Finishing Standard, latest edition) of the manufacturer/supplier’s choice.

b) All defects in exposed faces shall be repaired, filled, and sanded before painting.

3.4.3 Stringers, Glued up

a) Exposed plys within stringers shall be of similar thickness.

b) Face plys shall be consistent between like parts within the stair.

c) s of plys in a shall be staggered.

d) Stringer plys shall be glued and clamped to provide and flush s.

e) For edge gluing requirements see Exceptions to Material Requirements, Exposed Stringers and s.

3.4.4 Treads (Including Winders)

a) projections and profiles shall be consistent throughout the stairway.

b) Grain shall run parallel to the leading edge of the .

a) Tread ends shall:

| Premium | Custom | Economy |

|---|---|---|

| Be returned to match the leading edge of the tread and conceal all exposed end grain, including end grain of the | Be returned to match the leading edge of the tread and conceal end grain of the tread | Have profiled ends match the leading edge of the tread |

b) Shall be securely attached to ensure a tight fit to the end of the tread. Gaps shall not exceed 20 percent of the perimeter and shall not exceed:

| Premium | Custom | Economy |

|---|---|---|

| .4 mm [.016″] | .4 mm [.016″] | .8 mm [.031″] |

c) Shared surfaces of tread and return shall be sanded flush.

d) Grain orientation of curved returns shall:

| Premium | Custom | Economy |

|---|---|---|

| Minimize exposed end grain on the edge | Minimize exposed end grain on the edge | Be at the option of the manufacturer/supplier |

e) Returned ends of winders in curved stairways shall:

| Premium | Custom | Economy |

|---|---|---|

| Have both edges of the return concentric with curve of stair | Have both edges of the return concentric with curve of stair | Be at the option of the manufacturer/ supplier |

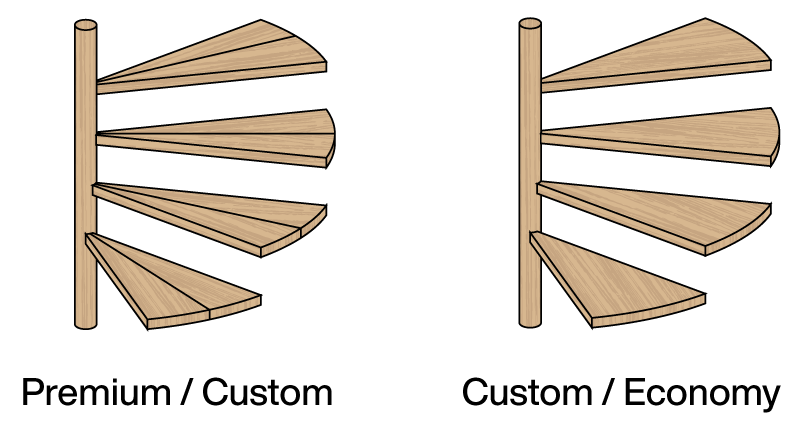

a) Grain direction shall (See Figure 98):

| Premium | Custom | Economy |

|---|---|---|

| Run parallel to the leading and trailing edge of the tread | Be at the option of the manufacturer/ supplier | Be at the option of the manufacturer/ supplier |

Figure 98

a) Exposed end grain is permitted.

3.4.5 Risers

a) Shall be a minimum of:

| Premium | Custom | Economy |

|---|---|---|

| 19.1 mm [.750″] thick | 19.1 mm [.750″] thick | 12.7 mm [.500″] thick |

a) Shall be a minimum of:

| Premium | Custom | Economy |

|---|---|---|

| 19.1 mm [.750″] thick | 19.1 mm [.750″] thick | 12.7 mm [.500″] thick |

3.4.6 Guard and Handrail Components

a) At connections to stair components other than rails, gaps shall not exceed:

| Premium | Custom | Economy |

|---|---|---|

| .8 mm [.031″] | .8 mm [.031″] | 1.6 mm [.063″] |

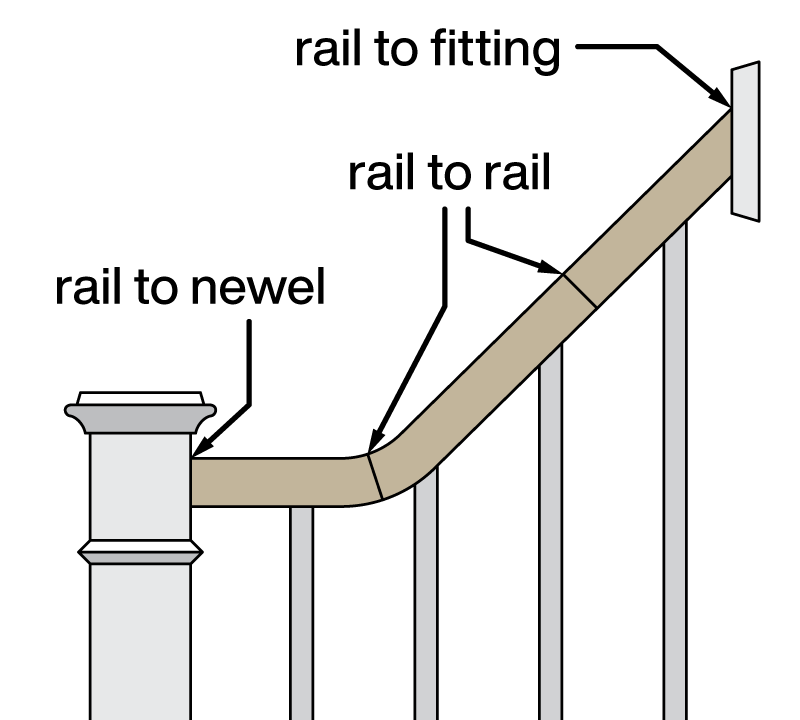

a) All to rail and rail to fitting joints shall be sanded and/or sculpted for seamless profile alignment to the following flushness tolerances:

| Premium | Custom | Economy |

|---|---|---|

| .4 mm [.016″] | .4 mm [.016″] | .8 mm [.031″] |

b) At rail to newel, rail to rail, and rail to fitting, gaps (See Figure 102) shall not exceed 20 percent of the joint perimeter and shall not exceed:

| Premium | Custom | Economy |

|---|---|---|

| .4 mm [.016″] | .4 mm [.016″] | .8 mm [.031″] |

Figure 102

3.4.7 Fittings

a) Fitting material shall be:

| Premium | Custom | Economy |

|---|---|---|

| Compatible for color within fitting | Compatible for color within fitting | At the option of the manufacturer/supplier |

| Compatible for color with adjacent components | Compatible for color with adjacent components |

b) Finger joints are:

| Premium | Custom | Economy |

|---|---|---|

| Not permitted | Not permitted | Permitted at lower plys of vertical drops of goosenecks |

c) Countersunk metal s are permitted, provided the slots have been filled and sanded flush.

a) Shall be closed-grained wood.

b) Plugs at joints are permitted provided they are sanded flush.

c) Countersunk metal splines are permitted, provided the slots have been filled and sanded flush.

3.4.8 Guard, In-Fill

a) At round end (no shoulder) in drilled holes, gaps shall not exceed:

| Premium | Custom | Economy |

|---|---|---|

| .4 mm [.016″] | .8 mm [.031″] | 1.6 mm [.063″] |

b) At round or square end (with shoulder), where not in plow, gaps shall not exceed:

| Premium | Custom | Economy |

|---|---|---|

| .4 mm [.016″] | .8 mm [.031″] | .8 mm [.031″] |

c) At square end in plow with fillet, gaps shall not exceed:

| Premium | Custom | Economy |

|---|---|---|

| .8 mm [.031″] | .8 mm [.031″] | 1.6 mm [.063″] |

d) All joints in wood in-fill panels and panel systems shall be smooth and flush.

a) Metal s and newels with shoes shall have:

| Premium | Custom | Economy |

|---|---|---|

| Epoxy shoe centered on baluster or newel and fit to match pitch of stair | Epoxy shoe centered on baluster or newel and fit to match pitch of stair | Shoes at the option of the manufacturer/ supplier |

| Set screws not permitted | Set screws not permitted | Set screws are permitted at the option of the manufacturer/ supplier |

b) Metal balusters and newels without shoes shall be:

| Premium | Custom | Economy |

|---|---|---|

| Mortised to fit end of baluster or newel | Mortised to fit end of baluster or newel | At the option of the manufacturer/ supplier |

a) All fitting and hardware components shall have compatible finish.

b) Exposed cable ends are not permitted.

c) All sections of cable in-fill shall be tensioned equally.

d) Where cables pass through wood posts at vertical or horizontal transitions, post protectors shall be used.

e) Spreader bars shall be spaced equally and securely attached.

f) Bushings shall be used to isolate reactive materials and prevent electrolysis.

a) All hardware components shall have compatible finish.

b) All glass shall be compatible in appearance.

a) At round end in drilled holes, gaps shall not exceed:

| Premium | Custom | Economy |

|---|---|---|

| .8 mm [.031″] | .8 mm [.031″] | 1.6 mm [.063″] |

b) Where not in plow and without shoes, gaps shall not exceed:

| Premium | Custom | Economy |

|---|---|---|

| 1.6 mm [.063″] | 1.6 mm [.063″] | 2.4 mm [.094″] |

c) Where in plow, gaps shall not exceed:

| Premium | Custom | Economy |

|---|---|---|

| 1.6 mm [.063″] | 1.6 mm [.063″] | 2.4 mm [.094″] |

d) Metal in-fill balusters with shoes shall have:

| Premium | Custom | Economy |

|---|---|---|

| Epoxy shoe centered on baluster or newel and fit to match of stair | Epoxy shoe centered on baluster or newel and fit to match pitch of stair | Shoes at the option of the manufacturer/supplier |

| Set screws not permitted | Set screws not permitted | Set screws are permitted at the option of the manufacturer/supplier |

e) Metal in-fill balusters without shoes shall be securely attached and:

| Premium | Custom | Economy |

|---|---|---|

| Mortised to fit ends | Mortised to fit ends | Mortised at the option of the manufacturer/supplier |

3.4.9 Well-Hole Trim

a) Outside corners shall be mitered (See Figure 100).

b) Moulded components at inside corners shall be (See Figure 100):

| Premium | Custom | Economy |

|---|---|---|

| d | Coped | Mitered or coped |

c) at inside corners shall be butted (See Figure 100).

d) Joinery of well-hole trim requires (See Figure 100):

| Premium | Custom | Economy |

|---|---|---|

| Exposed trimmed ends shall be miter returned | Exposed trimmed ends shall be profiled or miter returned | Exposed trimmed ends at the option of the installer |

| Multiple joints in shall not be within 1219 mm [48″] of another joint in the run, including corners | Multiple joints in running trim shall not be within 914 mm [36″] of another joint in the run, including corners | Multiple joints in running trim shall not be within 610 mm [24″] of another joint in the run, including corners |

e) Fasteners and fastening include the use of finish nails, trim screws, staples, pins, and/ or construction adhesive for inconspicuous fastening. Staples with a crown exceeding 4.8 mm [.188″] wide are not permitted.

f) Exposed fasteners shall be inconspicuous.

g) Exposed fasteners shall be countersunk through the exposed material surface, kept to a minimum, and shall be:

| Premium | Custom | Economy |

|---|---|---|

| Set in quirks and reliefs where possible | Set in quirks and reliefs where possible | Fastened in placement at the option of the installer |

Figure 100

a) Nosing of landing tread, at the exit of a flight, shall be made to match the thickness, profile, and projection of the treads throughout stairway.

3.4.10 Staircase (Assembled Unit)

a) Stairs at open-cut stringers or skirt boards shall:

| Premium | Custom | Economy |

|---|---|---|

| Be mitered to s | Be mitered to risers | Attachment of risers at the option of the manufacturer/supplier |

b) Treads at open-cut stringers shall:

| Premium | Custom | Economy |

|---|---|---|

| Have nosing applied with no visible fasteners | Have tread return nosing applied | Have end of tread profiled or applied tread return nosing at the option of the manufacturer/supplier |

| Have end of tread return nosing returned with no end grain visible | Have end of tread return nosing profiled with visible end grain at the option of the manufacturer/supplier |

c) Brackets at open-cut stringers shall be mitered to risers.

d) Tread returns shall be cut to eliminate end grain at the front edge.

a) At s:

| Premium | Custom | Economy |

|---|---|---|

| Treads and risers shall be mortised into stringers | Treads and risers shall be mortised into stringers | Butt joints are permitted |

b) Knee walls shall be capped.